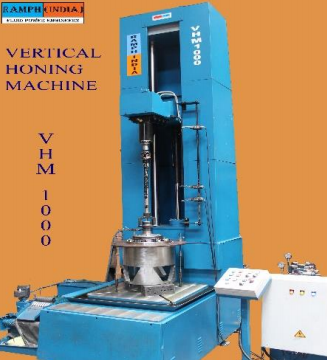

Vertical Honing Machine

A vertical honing machine is a precision engineering tool primarily used for finishing and refining the internal surfaces of cylindrical components. It operates through a process known as honing, which involves the use of abrasive stones or tools that rotate and oscillate against the workpiece. This machine is particularly beneficial for achieving high levels of accuracy and a superior surface finish, making it ideal for industries that require tight tolerances, such as automotive, aerospace, and manufacturing. The vertical design of the honing machine allows for efficient handling of larger or heavier workpieces, ensuring stability during operation.

One of the key advantages of vertical honing machines is their versatility; they can be adapted for various honing applications, from simple tasks like deburring to complex processes that improve the dimensional accuracy of parts. The machine's automation capabilities enable consistent performance and reduced cycle times, contributing to increased productivity in manufacturing environments. Additionally, advanced features such as programmable controls and real-time monitoring systems help operators maintain precise control over the honing process, ensuring quality results.

With the growing demand for high-performance components in various industries, the importance of vertical honing machines continues to rise. They not only enhance the operational efficiency of production lines but also play a crucial role in extending the lifespan and reliability of critical components. As technology advances, vertical honing machines are evolving, incorporating innovative features such as improved abrasive materials and enhanced cooling systems, further optimizing their performance and adaptability. Overall, vertical honing machines represent a vital asset for manufacturers seeking to meet stringent quality standards while maximizing operational efficiency.