Honing Machine

Types of Honing Machines

-

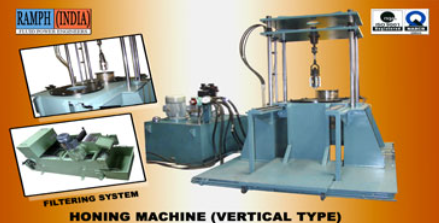

Vertical Honing Machines: These machines stand upright, and the workpiece is usually mounted in a fixture. They are commonly used for larger and heavier components.

-

Horizontal Honing Machines: In these machines, the honing action is performed horizontally. They are typically used for smaller, elongated components.

-

Hand-Honing Tools: These are portable or hand-held honing devices for manual operation, suitable for on-site repairs or where machinery cannot be used.

-

CNC Honing Machines: These machines are controlled by a computer program, which provides high precision and automation. They are used for complex projects and high-volume production environments.

Advantages of Honing

- Accuracy: Achieves precise internal dimensions and tolerances.

- Surface Finish: Provides an excellent surface finish, often required for sealing surfaces and reducing friction.

- Efficiency: Although generally slower than other material removal processes, honing is more efficient for achieving certain final finish and accuracy.

- Versatility: Capable of working on a variety of materials, including hardened steels, ceramics, and composites.