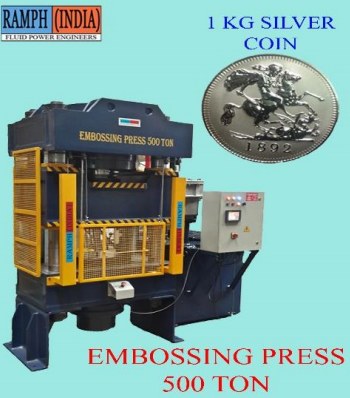

Embossing Hydraulic Press

An embossing hydraulic press is a powerful machine used to create raised or recessed designs on various materials, including metal, plastic, and leather. This process, known as embossing, enhances the aesthetics, functionality, and value of products by adding intricate patterns, textures, or logos. Hydraulic presses are favored for embossing due to their precision, power, and ability to apply uniform pressure over a large surface area. In this article, we will explore the mechanics, applications, advantages, and considerations of using an embossing hydraulic press.

Mechanics of an Embossing Hydraulic Press

A hydraulic press operates on Pascal's law, which states that when pressure is applied to a confined fluid, it is transmitted equally in all directions. In an embossing hydraulic press, this principle is used to generate a large amount of force with minimal input. The press typically consists of a hydraulic cylinder, a pump, a motor, and a control system. The cylinder contains a piston that moves within the cylinder, driven by the hydraulic fluid. As the pump pushes the fluid into the cylinder, the piston is forced downwards, applying pressure to the material placed between the embossing dies.

The embossing die set is a crucial component of the press. It typically consists of a male and a female die, where the male die contains the raised design, and the female die has the corresponding recessed design. When the material is placed between these dies and the press is activated, the dies come together, pressing the material and creating the embossed design. The precision with which the dies are manufactured determines the quality and detail of the embossing.

Applications of Embossing Hydraulic Presses

Embossing hydraulic presses are used across various industries for different applications, including:

-

Metalworking: In the metal industry, embossing presses are used to create decorative patterns on metal sheets, which are then used in architectural applications, automotive parts, and consumer goods. For example, stainless steel panels with embossed patterns are often used in building facades and interior designs.

-

Leather and Textiles: In the fashion industry, embossing hydraulic presses are used to create textured patterns on leather and fabric. This process is commonly used to produce luxury leather goods such as handbags, wallets, and belts. The embossed patterns add a tactile quality to the material, enhancing its aesthetic appeal.

-

Packaging: The packaging industry uses embossing presses to create logos, branding, and decorative patterns on packaging materials such as cardboard, plastic, and aluminum. Embossed packaging not only enhances the visual appeal of the product but also adds a tactile element that can make the product stand out on the shelf.

-

Plastic Manufacturing: Embossing hydraulic presses are used to imprint designs on plastic components, which are used in various industries, including automotive, electronics, and consumer goods. The embossed patterns can serve functional purposes, such as improving grip, as well as decorative purposes.

-

Signage and Nameplates: Embossing presses are used to create raised lettering and designs on metal and plastic nameplates, badges, and signage. These embossed elements are durable and have a high-quality appearance, making them suitable for industrial and commercial applications.

Advantages of Using an Embossing Hydraulic Press

Embossing hydraulic presses offer several advantages, making them a preferred choice for many industrial applications:

-

Precision and Consistency: Hydraulic presses provide uniform pressure across the entire surface area of the material, ensuring consistent embossing results. This is particularly important in applications where high precision is required, such as in the creation of detailed logos or intricate patterns.

-

Versatility: These presses can be used on a wide range of materials, including metals, plastics, and leather. The ability to adjust the pressure and temperature settings allows for customization based on the material being embossed.

-

High Production Efficiency: Hydraulic presses are capable of producing large volumes of embossed products in a short amount of time. This makes them ideal for mass production environments where speed and efficiency are critical.

-

Customization: Embossing dies can be customized to create specific designs, logos, or patterns. This allows manufacturers to create unique, branded products that stand out in the market.

-

Durability: The embossing process not only adds aesthetic value but also increases the durability of the material. For example, embossed metal sheets are less prone to wear and tear, making them suitable for heavy-duty applications.

Considerations When Using an Embossing Hydraulic Press

While embossing hydraulic presses offer numerous advantages, there are also some important considerations to keep in mind:

-

Die Design and Manufacturing: The quality of the embossing is heavily dependent on the design and manufacturing of the dies. Poorly designed or manufactured dies can result in subpar embossing results, including uneven patterns or incomplete impressions.

-

Material Compatibility: Different materials react differently to the embossing process. It is essential to choose the right combination of pressure, temperature, and die material to achieve the desired results without damaging the material.

-

Maintenance and Safety: Like any industrial machinery, embossing hydraulic presses require regular maintenance to ensure optimal performance and longevity. Additionally, safety measures must be in place to protect operators from the high pressures and temperatures involved in the process.

-

Initial Investment: The cost of purchasing and setting up an embossing hydraulic press can be significant. However, this investment can be justified by the long-term benefits, including high production efficiency and the ability to produce high-quality, customized products.

Conclusion

Embossing hydraulic presses play a crucial role in various industries by enabling the creation of detailed, high-quality embossed designs on a wide range of materials. Their precision, versatility, and efficiency make them indispensable tools for manufacturers looking to enhance the aesthetic and functional value of their products. By understanding the mechanics, applications, advantages, and considerations of using an embossing hydraulic press, businesses can make informed decisions about integrating this technology into their production processes.