Hydraulic Cylinders

Hydraulic cylinders are pivotal components in hydraulic systems, utilized across various industries for their efficiency and power in converting fluid energy into mechanical force. These cylinders function based on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. A typical hydraulic cylinder consists of a cylindrical barrel, a piston, and two end caps. The barrel houses the piston, which moves back and forth, creating linear motion. When hydraulic fluid is pumped into the cylinder, it pushes the piston, generating force that can lift heavy loads, move machinery, or perform other mechanical tasks.

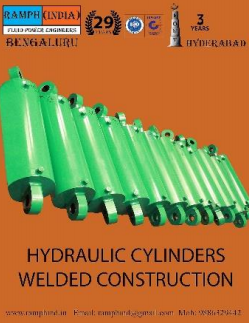

Hydraulic cylinders come in various designs and configurations, including single-acting and double-acting cylinders. Single-acting cylinders use fluid pressure to move the piston in one direction, while a spring or gravity returns it to its original position. In contrast, double-acting cylinders use hydraulic pressure for both the extending and retracting movements, providing greater versatility and control. These cylinders are also categorized based on their construction, such as tie rod, welded, or telescopic cylinders, each offering distinct advantages for specific applications.

Common applications of hydraulic cylinders include construction equipment like excavators and bulldozers, manufacturing machinery, automotive systems, and even aircraft controls. Their ability to produce significant force in a compact form makes them ideal for tasks requiring precision and power, such as lifting, pushing, and clamping. The durability and reliability of hydraulic cylinders are enhanced through materials designed to withstand high pressure and harsh operating conditions, ensuring long service life and minimal maintenance.

Safety is a crucial aspect of hydraulic cylinder design, as failures can lead to significant hazards. To mitigate risks, manufacturers often integrate features such as pressure relief valves, seals, and shock absorbers, ensuring the system can handle unexpected conditions. Regular maintenance checks are also vital to monitor for leaks, wear, and other issues that could compromise performance.

In recent years, advancements in technology have led to the development of smart hydraulic cylinders equipped with sensors that provide real-time data on performance and condition. This innovation allows for predictive maintenance, optimizing the efficiency of hydraulic systems while minimizing downtime. Overall, hydraulic cylinders are indispensable in modern engineering, providing the necessary power and control to drive various industrial processes. Their ongoing evolution reflects the demand for more efficient, reliable, and safe hydraulic solutions across diverse sectors.