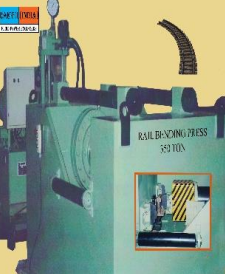

Rail Bending Press

A rail bending press is a specialized industrial machine used for bending steel rails to achieve the desired curvature or angle. These machines are essential in industries such as railway construction, shipbuilding, and heavy machinery manufacturing, where precision in bending rail sections is critical to maintaining structural integrity and performance. Rail bending presses are robust in design, typically featuring hydraulic or mechanical systems that generate the high forces needed to bend thick and heavy steel rails.

The working principle of a rail bending press involves placing the rail between a series of press rollers or a die, with hydraulic cylinders or mechanical arms applying force to create the bend. The machine ensures that the rail bends uniformly, avoiding any deformation or damage. This process is essential for shaping rails that need to conform to specific track layouts, particularly in areas with curved paths, such as railways or crane tracks.

Modern rail bending presses are equipped with computer numerical control (CNC) technology, which allows for precise programming of the bending angles and forces, ensuring consistent and accurate results. This precision is crucial for industries where the slightest deviation in the curvature of rails could lead to operational inefficiencies or safety hazards.

In addition to bending new rails, rail bending presses can also be used for repair work, where existing rails need to be reshaped or straightened. They play a vital role in both production and maintenance processes, increasing the longevity of rail systems and ensuring smooth operation. The versatility and strength of rail bending presses make them an indispensable tool in industries that require large-scale metal forming and shaping.