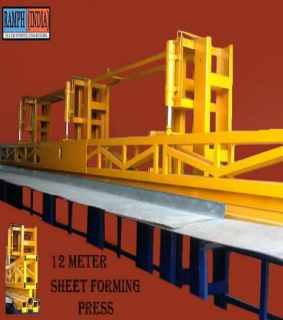

Sheet Forming Press

A sheet forming press is an industrial machine used to shape metal sheets into specific forms and components through various forming processes, such as stamping, bending, and drawing. These presses apply high force to a sheet of metal, causing it to conform to the shape of a die or mold. Sheet forming presses are widely utilized in industries like automotive manufacturing, aerospace, and appliance production, where precision and consistency in component fabrication are critical.

The press can operate using different mechanisms such as hydraulic, mechanical, or pneumatic systems, each suited to specific types of materials and desired outcomes. Hydraulic presses are known for their flexibility and ability to apply consistent pressure, making them ideal for complex shapes and deeper draws. In contrast, mechanical presses are often favored for high-speed operations and are used in tasks that require repetitive, high-volume production.

The process begins by placing the metal sheet into the press, where a punch pushes the material into a die, shaping it into the desired form. The force applied must be carefully calibrated to avoid tearing or deforming the material while ensuring it meets design specifications. Modern sheet forming presses often include advanced control systems for precise adjustments, ensuring high-quality output and reducing material waste.

In addition to the press itself, other elements like die designs, lubrication, and temperature control are essential for the successful operation of a sheet forming press.