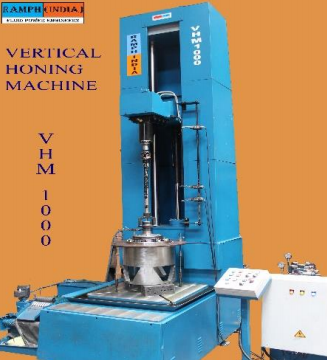

Vertical Honing Machine Manufacture

Introduction to Vertical Honing Machines

Vertical honing machines are precision tools designed for the finishing of cylindrical surfaces. These machines utilize an abrasive honing process that enhances the dimensional accuracy and surface finish of workpieces. Commonly used in manufacturing sectors such as automotive, aerospace, and heavy machinery, vertical honing machines are crucial for applications requiring high precision and quality.

Key Features of Vertical Honing Machines

-

Design and Construction: Vertical honing machines are characterized by their upright configuration, which allows for the efficient processing of long workpieces. The vertical design ensures better chip removal and coolant flow, resulting in improved surface finish and reduced wear on tools.

-

Honing Process: The honing process involves the use of abrasive stones or sticks that oscillate and rotate around the workpiece. The controlled motion and precise pressure applied by the honing tools allow for the removal of minute amounts of material, resulting in a smooth, accurate finish.

-

Control Systems: Modern vertical honing machines are equipped with advanced control systems, allowing for precise adjustments in speed, pressure, and stroke length. This level of control enables manufacturers to achieve tight tolerances and repeatable results, making them ideal for high-precision applications.

-

Versatility: Vertical honing machines can accommodate a wide range of materials, including metals, plastics, and ceramics. Their versatility makes them suitable for various industries, from producing hydraulic cylinders to finishing engine blocks.

Manufacturing Process of Vertical Honing Machines

-

Design and Engineering: The manufacturing of vertical honing machines begins with detailed design and engineering. Skilled engineers create CAD models to ensure that the machine will meet specific industry standards and customer requirements. Considerations include the machine's size, capacity, and operational features.

-

Material Selection: High-quality materials are crucial for durability and performance. Manufacturers typically use robust metals such as cast iron or steel for the frame and components, ensuring stability and longevity. Abrasive materials are carefully chosen based on the intended application and required surface finish.

-

Machining and Fabrication: Once the design and materials are finalized, the components are machined and fabricated using advanced techniques such as CNC machining, welding, and surface grinding. Precision is critical during this stage to ensure that all parts fit together accurately.

-

Assembly and Testing: After machining, the components are assembled to create the complete honing machine. Each machine undergoes rigorous testing to verify its performance, including checks for alignment, functionality, and adherence to safety standards. Manufacturers often conduct test runs using actual workpieces to ensure quality and precision.

-

Quality Assurance: Quality assurance processes are implemented throughout the manufacturing cycle. This includes inspections at various stages, ensuring that the final product meets the required specifications and standards. Certifications such as ISO or CE may be obtained to demonstrate compliance with international quality standards.

Market Trends and Innovations

The market for vertical honing machines is witnessing several trends, including increased automation, the integration of Industry 4.0 technologies, and a growing emphasis on sustainability. Manufacturers are adopting smart technologies, enabling real-time monitoring and data collection, which enhances operational efficiency and reduces downtime.

Conclusion

Vertical honing machines play a vital role in achieving high precision and quality in various manufacturing processes. With advancements in technology and engineering, the production of these machines continues to evolve, offering manufacturers reliable and efficient solutions for their honing needs. As industries demand greater accuracy and efficiency, vertical honing machines will remain essential tools in the manufacturing landscape.