A rail bending machine is a specialized piece of equipment used to bend rails to precise angles, commonly used in industries like construction, railroads, and shipbuilding. These machines are designed to shape metal rails efficiently, ensuring accuracy and consistency in applications requiring curved or bent rails. The manufacturing of rail bending machines is a specialized industry, involving complex engineering, precision machinery, and high-quality materials. Companies that manufacture these machines cater to industries that require durable, reliable, and high-performance rail bending solutions.

Importance of Rail Bending Machines

In various industries, the need for rail bending is crucial to ensure structures, tracks, and infrastructure projects are aligned with design specifications. Traditional methods of manually bending metal are labor-intensive and prone to errors. A rail bending machine automates this process, providing consistent results, reducing labor costs, and increasing overall productivity. These machines are commonly used for shaping railway tracks, industrial rails, and heavy-duty metal components that require precise curvature.

Types of Rail Bending Machines

There are several types of rail bending machines available in the market. These machines can differ based on their design, functionality, and intended use. Some common types include:

-

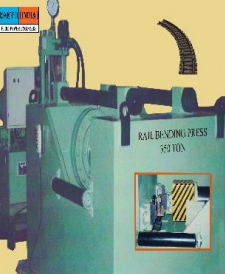

Hydraulic Rail Bending Machines: These machines use hydraulic pressure to bend rails. They are known for their strength and ability to bend large and heavy rails. Hydraulic rail benders are ideal for industrial use, especially in railway construction and shipbuilding industries.

-

Manual Rail Bending Machines: Designed for smaller projects, these machines require manual input and are usually more cost-effective. Though not as powerful as hydraulic machines, they are still effective for smaller-scale bending tasks.

-

Electric Rail Bending Machines: Powered by electric motors, these machines offer automated operation, allowing for higher precision and faster processing times. They are commonly used in factories where precision and efficiency are critical.

Key Features of a High-Quality Rail Bending Machine

Manufacturers of rail bending machines focus on integrating several key features into their products to ensure top performance:

-

Precision Bending: High-quality machines allow for accurate bending, which is crucial for industries like railroads, where even slight inaccuracies can lead to operational issues.

-

Durability: These machines are typically made from heavy-duty steel and other robust materials to ensure long-lasting performance, even in tough working conditions.

-

Automation: Modern machines come with automated features, including digital controls and programmable settings that make the bending process efficient and less reliant on manual input.

-

Safety Features: Since these machines deal with heavy materials, manufacturers incorporate safety mechanisms like emergency stop buttons, safety guards, and sensors to prevent accidents.

Manufacturing Process

Manufacturers of rail bending machines follow a stringent manufacturing process, ensuring each machine meets industry standards. The process generally involves:

-

Design and Engineering: The design of a rail bending machine requires advanced engineering and software tools. Manufacturers create 3D models to optimize the machine's design and functionality before production.

-

Material Selection: High-quality steel and hydraulic components are selected for their durability and resistance to wear and tear.

-

Fabrication: The components of the machine are fabricated using CNC machines and other precision tools to ensure exact dimensions and fit.

-

Assembly: After fabrication, the components are assembled with high accuracy to form the final product.

-

Quality Testing: Each machine undergoes rigorous testing, including stress tests and performance evaluations, to ensure it meets industry standards.

Leading Manufacturers

There are several reputed rail bending machine manufacturers globally, specializing in providing custom solutions to their clients. Some of the top manufacturers focus on innovation, integrating advanced technologies like automation and digital controls to enhance the machine’s performance. They also provide customer support, maintenance services, and spare parts to ensure their machines run smoothly over time.

In conclusion, the rail bending machine is an essential tool in various industries, and its manufacturing involves high-quality engineering and precision. Investing in a reliable rail bending machine is critical for ensuring smooth operations in any project that requires metal rail shaping.