Contact : +917338368993

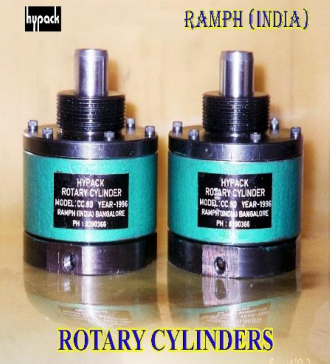

Understanding Rotary Cylinders: Applications, Benefits, and Mechanisms

Introduction to Rotary Cylinders

Rotary cylinders are pivotal components in various industrial applications, particularly in the fields of automation, manufacturing, and engineering. These devices convert linear motion into rotational movement, enabling machinery to perform complex tasks efficiently. Understanding the mechanics and benefits of rotary cylinders is essential for industries looking to enhance their operational efficiency.

How Rotary Cylinders Work

A rotary cylinder functions through the principle of converting linear motion into rotary motion. Typically, a piston within the cylinder moves back and forth due to hydraulic or pneumatic pressure. This movement is then translated into rotational motion via a connecting mechanism, such as gears or pulleys. The design allows for precise control over speed and torque, making rotary cylinders versatile for a wide range of applications.

Types of Rotary Cylinders

-

Hydraulic Rotary Cylinders: These utilize hydraulic fluid to generate force and control motion. They are ideal for heavy-duty applications where significant torque is required.

-

Pneumatic Rotary Cylinders: These operate using compressed air and are commonly used in lighter applications. Pneumatic cylinders are known for their speed and efficiency.

-

Electric Rotary Cylinders: These utilize electric motors to achieve rotational movement, offering precise control and high efficiency, making them suitable for automated systems.

Applications of Rotary Cylinders

Rotary cylinders are used in numerous industries, including:

-

Manufacturing: In assembly lines, rotary cylinders help in the automation of processes such as rotating parts for assembly, packaging, and material handling.

-

Automotive: In the automotive industry, rotary cylinders play a crucial role in various machinery and equipment, enabling the assembly and inspection of automotive components.

-

Food and Beverage: Rotary cylinders are employed in bottling and packaging machines, ensuring efficient operation and consistency in production.

-

Aerospace: In aerospace applications, rotary cylinders are used in systems requiring precision movement and reliability, such as control surfaces and landing gear mechanisms.

-

Construction: These cylinders can be found in construction machinery, aiding in tasks such as lifting, rotating, and moving heavy materials.

Benefits of Using Rotary Cylinders

-

Efficiency: Rotary cylinders provide smooth and efficient motion, reducing energy consumption and increasing overall productivity.

-

Precision: With the ability to control speed and torque, rotary cylinders offer high precision, making them suitable for applications requiring exact movements.

-

Durability: Built to withstand harsh environments and heavy use, rotary cylinders are designed for longevity, reducing maintenance costs over time.

-

Versatility: Their adaptability makes rotary cylinders suitable for various applications across different industries, allowing businesses to streamline operations.

-

Compact Design: Rotary cylinders often have a compact design, making them ideal for applications with limited space while still providing high performance.

Conclusion

Rotary cylinders are essential components in modern industrial applications, contributing to automation and efficiency across multiple sectors. Their ability to convert linear motion into rotational movement makes them invaluable for tasks that require precision and reliability. By understanding the types, applications, and benefits of rotary cylinders, businesses can make informed decisions to enhance their operational capabilities. Whether in manufacturing, automotive, or aerospace industries, rotary cylinders play a crucial role in driving innovation and efficiency. For those looking to invest in rotary cylinders, it is essential to choose the right type and specifications that best fit the intended application to maximize performance and productivity.