Office

172/A 2, 11th Main, 3rd Phase, Peenya Industrial Area Near Siddhivinayak Temple, Laggere

Bangalore , karnataka

India (560058)

Contact : +917338368993

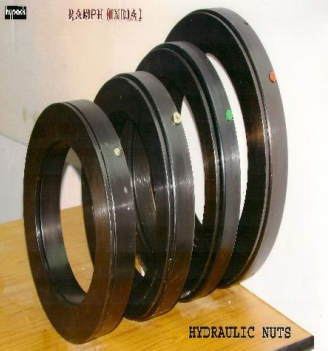

Hydraulic Nut

A hydraulic nut is a specialized mechanical component used in heavy-duty applications where conventional tightening methods may not be sufficient to achieve the required clamping force. It offers a reliable and efficient solution for the precise application of torque in high-stress environments, such as industrial machinery, turbines, or large equipment. This article will explore the key features, applications, benefits, and SEO-friendly information on hydraulic nuts.

A hydraulic nut is a device that uses hydraulic pressure to achieve uniform and controlled tightening of large bolts or studs. It consists of a piston and a hydraulic chamber, which allows the nut to be tightened or loosened using hydraulic pressure. This method is particularly advantageous in cases where high tension forces are required, as it enables users to apply force more easily and accurately compared to manual tools.

In a typical setup, the hydraulic nut is threaded onto the bolt or stud that needs to be tensioned. Hydraulic oil is then pumped into the nut, causing the piston to push against the bolt’s flange or surface. This action stretches the bolt, allowing the nut to be tightened or adjusted. Once the desired tension is reached, the hydraulic pressure is released, and the bolt maintains its clamping force.

Hydraulic nuts are commonly used in heavy-duty industries that require precise torque and clamping force, including:

Hydraulic nuts are indispensable tools in industries that require the secure and precise fastening of large bolts. Their ability to provide uniform tension, ease of use, and safety make them an ideal choice for heavy machinery, power generation, and other high-demand applications. Investing in hydraulic nuts can significantly improve operational efficiency, reduce maintenance costs, and increase the safety of industrial equipment.