Contact : +917338368993

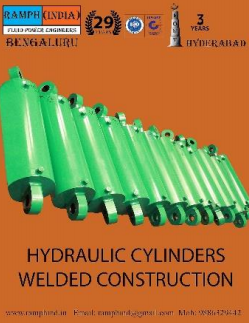

Understanding Hydraulic Cylinders: Function, Types, and Applications

Hydraulic cylinders are essential components in various industries, serving as actuators that convert hydraulic energy into mechanical force. These devices play a pivotal role in powering machinery and equipment, making them vital in construction, manufacturing, automotive, and more.

What is a Hydraulic Cylinder?

A hydraulic cylinder consists of a cylindrical barrel, a piston, and a rod. When hydraulic fluid is pumped into the cylinder, it creates pressure that pushes the piston, generating linear motion. This motion can be harnessed to lift, push, pull, or rotate loads, making hydraulic cylinders incredibly versatile.

Types of Hydraulic Cylinders

-

Single-Acting Cylinders: These cylinders have a piston that moves in one direction when hydraulic fluid is applied. A spring or gravity returns the piston to its original position. They are often used in applications like clamping and lifting.

-

Double-Acting Cylinders: These allow fluid to enter both sides of the piston, enabling it to move in both directions. This design provides greater control and force, making them suitable for tasks requiring precise positioning, such as in construction equipment.

-

Telescopic Cylinders: Featuring multiple nested cylinders, these allow for significant extension in a compact space. They are commonly used in applications like dump trucks, where a high lift is required in a limited area.

-

Rotary Actuators: These cylinders convert hydraulic pressure into rotational motion. They are used in applications like steering systems in vehicles and in industrial machinery.

Applications of Hydraulic Cylinders

Hydraulic cylinders are utilized across numerous sectors due to their strength and efficiency. Here are some common applications:

-

Construction: Hydraulic cylinders power heavy machinery such as excavators, bulldozers, and cranes. They enable operators to lift heavy loads, dig, and move materials efficiently.

-

Manufacturing: In factories, hydraulic cylinders are used in machines for stamping, bending, and assembling parts. They provide the necessary force to perform these operations effectively.

-

Automotive: Hydraulic systems are integral to braking systems, power steering, and lifts in service stations. They enhance the safety and functionality of vehicles.

-

Agriculture: Tractors and other farming equipment rely on hydraulic cylinders for tasks like lifting plows, adjusting seeders, and loading materials.

-

Marine: Hydraulic cylinders are used in ships for steering, stabilizing, and operating various machinery on board.

Advantages of Hydraulic Cylinders

-

High Power-to-Weight Ratio: Hydraulic cylinders can generate significant force without requiring excessive space or weight.

-

Precise Control: They offer precise control over motion, making them ideal for applications where accuracy is critical.

-

Durability: Designed to withstand harsh conditions, hydraulic cylinders have a long service life, reducing maintenance costs.

-

Versatility: With various types and configurations available, hydraulic cylinders can be customized for specific applications, making them suitable for diverse industries.

Conclusion

Hydraulic cylinders are fundamental to the efficient operation of many machines and systems. Their ability to convert hydraulic energy into powerful linear motion enables them to perform critical tasks across various sectors. Understanding the different types and applications of hydraulic cylinders can help businesses optimize their use, enhance productivity, and reduce operational costs. Whether in construction, manufacturing, or agriculture, hydraulic cylinders continue to be indispensable in modern engineering and machinery.