Hydraulic press machines are essential in various industries due to their capability to exert immense force and perform numerous operations such as molding, forging, clinching, blanking, punching, deep drawing, and metal forming. Among these, the H-type hydraulic press machine stands out for its versatility, precision, and adaptability. These machines are widely used in manufacturing, automotive, aerospace, and other sectors where high pressure and precise control are crucial.

Overview of H-Type Hydraulic Press Machines

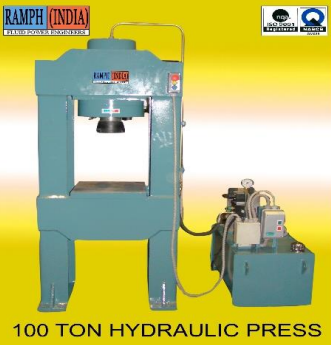

An H-type hydraulic press machine, as the name suggests, is designed in the shape of the letter "H," with the hydraulic cylinder placed centrally over the workpiece. This design provides stability and evenly distributed force, making it suitable for heavy-duty applications. The H-type press typically consists of a robust frame, hydraulic cylinder, hydraulic pump, control system, and work table.

The frame is usually constructed from high-grade steel or other durable materials to withstand the immense pressure exerted during operations. The hydraulic cylinder, powered by the hydraulic pump, generates the pressing force, which can range from a few tons to several thousand tons, depending on the machine's capacity. The control system allows precise manipulation of the pressing force, speed, and position, ensuring accurate and consistent results.

Manufacturing Process

Manufacturing H-type hydraulic press machines is a complex process that requires a deep understanding of engineering principles, materials science, and manufacturing techniques. The process begins with designing the machine based on the specific needs of the customer, including the required pressing force, size of the work table, stroke length, and other parameters.

-

Material Selection and Frame Construction: The first step in manufacturing is selecting the right materials. The frame, being the backbone of the machine, is typically made from high-strength steel. The steel is cut, machined, and welded to form the basic structure of the machine. The welding process is critical as it ensures the frame's integrity and ability to withstand high pressure without deforming.

-

Hydraulic System Assembly: Once the frame is ready, the hydraulic system is assembled. This system includes the hydraulic cylinder, pump, valves, and hoses. The cylinder is machined to precise tolerances to ensure smooth operation and long service life. The hydraulic pump, which can be powered by electricity or other means, is responsible for generating the necessary pressure. The entire hydraulic system is meticulously tested for leaks, pressure capacity, and performance.

-

Control System Integration: The next step is integrating the control system. Modern H-type hydraulic press machines are often equipped with sophisticated electronic controls that allow the operator to set and monitor various parameters, such as pressure, speed, and stroke length. These controls can be manual, semi-automatic, or fully automatic, depending on the machine's design and the customer's requirements.

-

Final Assembly and Testing: After the hydraulic system and control system are in place, the machine undergoes final assembly. This includes installing the work table, aligning the cylinder with the frame, and connecting all the systems. Once assembled, the machine undergoes rigorous testing to ensure it meets all specifications and operates safely and efficiently.

Applications and Advantages

H-type hydraulic press machines are used in a wide range of applications due to their versatility. They are commonly found in industries such as automotive manufacturing, where they are used for stamping and forming metal parts, and in the production of household appliances, where they are used for molding plastic components.

One of the main advantages of H-type hydraulic press machines is their ability to apply uniform pressure across the entire workpiece, resulting in consistent and high-quality output. They are also known for their reliability, ease of maintenance, and ability to handle a variety of materials, including metals, plastics, and composites.

Conclusion

The H-type hydraulic press machine is a crucial tool in modern manufacturing, offering unparalleled force and precision. Its robust construction, advanced hydraulic system, and versatile control options make it suitable for a wide range of industrial applications. As technology advances, these machines continue to evolve, incorporating new features and capabilities that further enhance their performance and efficiency. Whether used in heavy industry or precision manufacturing, the H-type hydraulic press machine remains a cornerstone of industrial production, driving innovation and quality in manufacturing processes worldwide.