Contact : +917338368993

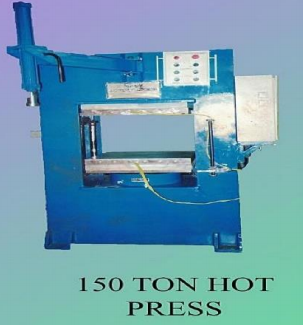

An H Type Hot Press Machine is a specialized industrial tool used primarily in the manufacturing and production sectors for tasks such as pressing, molding, and laminating. These machines are named for their distinctive "H" shaped frame, which provides enhanced stability and strength during high-pressure operations. If you are looking for an H Type Hot Press Machine Manufacturer, it’s crucial to understand the various factors that determine quality, efficiency, and reliability.

Features of H Type Hot Press Machines

H Type Hot Press Machines are known for their durability, precision, and robust design. They offer superior performance in tasks that require consistent pressure and temperature, such as forming, bonding, or laminating different materials, including metal, wood, and composites. Here are some essential features to look for in an H Type Hot Press Machine:

-

Sturdy Frame Construction: The H-shaped frame design ensures that the machine can withstand high pressure and provide uniform force distribution during operation. This is critical for ensuring consistent results, especially in applications like wood lamination and metal pressing.

-

Hydraulic System: These machines often come equipped with an advanced hydraulic system that ensures smooth operation and precise control over the pressing process. This system allows for efficient pressure control, resulting in better-quality end products.

-

Temperature Control: Many H Type Hot Press Machines have integrated temperature control systems, allowing the machine to maintain the desired heat levels during the pressing process. This feature is especially important in applications such as rubber molding, where precise temperature control is crucial for product quality.

-

Energy Efficiency: Modern machines are designed to consume less energy while still delivering high power output. This feature is essential for manufacturers aiming to reduce operational costs while maintaining efficiency.

-

Safety Features: Reputable manufacturers incorporate various safety mechanisms, such as overload protection and emergency stop buttons, ensuring the safety of operators.

Applications of H Type Hot Press Machines

These machines are versatile and are used in a variety of industries, including:

- Woodworking Industry: Used for veneer pressing, plywood lamination, and furniture production.

- Rubber and Plastics Industry: For molding and forming rubber and plastic components.

- Metalworking: Pressing and shaping metal sheets and components.

- Composite Materials: Used in industries that require the bonding of composite materials under high pressure and temperature.

Factors to Consider When Choosing an H Type Hot Press Machine Manufacturer

When selecting an H Type Hot Press Machine Manufacturer, it’s essential to evaluate several factors to ensure that you’re investing in a high-quality machine that meets your production needs:

-

Experience and Reputation: Look for manufacturers with a proven track record in producing reliable, high-performance machines. Check for customer reviews, case studies, and the company’s history in the industry.

-

Customization Options: Since different industries have specific requirements, a good manufacturer should offer customization options to meet your exact specifications. This includes options for frame size, pressure levels, and heating systems.

-

After-Sales Support: Comprehensive after-sales support, including installation, maintenance, and repair services, is critical. A reputable manufacturer should offer warranty coverage and have a dedicated support team to assist with any issues that arise during machine operation.

-

Compliance with International Standards: Ensure that the manufacturer adheres to international standards for quality, safety, and performance. Machines that are certified by organizations such as ISO (International Organization for Standardization) are more likely to meet rigorous performance and safety criteria.

-

Technology and Innovation: Manufacturers that invest in research and development often offer machines equipped with the latest technologies. These innovations can include energy-efficient hydraulic systems, automated controls, and improved safety mechanisms.

Top Manufacturers of H Type Hot Press Machines

When searching for a reliable H Type Hot Press Machine manufacturer, it is worth considering companies that have established themselves as leaders in the industry. Look for manufacturers that have a wide range of products and cater to various industries, ensuring that they have the experience and expertise to meet your specific requirements.

In conclusion, an H Type Hot Press Machine is a critical asset for businesses in industries such as woodworking, metalworking, and plastics. By choosing a reputable manufacturer that offers customization, after-sales support, and advanced features, you can ensure that your machine will perform efficiently and contribute to the success of your production line.