Contact : +917338368993

Forming Press for Aerospace Manufacturing: A Critical Tool in Precision Engineering

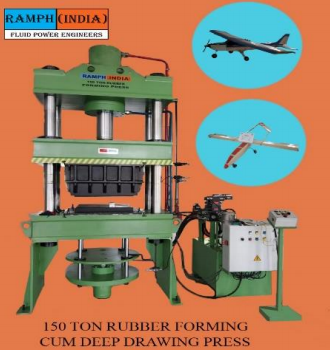

In the highly specialized field of aerospace manufacturing, precision, reliability, and efficiency are paramount. One of the key technologies that facilitate these essential qualities is the forming press. Forming presses are integral to the aerospace industry, where they are used to shape, form, and fabricate various components with exacting standards.

What is a Forming Press?

A forming press is a type of machine press that reshapes metal workpieces by applying high pressure. In aerospace manufacturing, these presses are used to produce a wide range of parts, including fuselage panels, wing components, engine casings, and various structural elements. The press operates by compressing the material, either through a die or mold, to achieve the desired shape. The process is essential for creating parts that require high strength-to-weight ratios, which are critical in aerospace applications.

Types of Forming Presses in Aerospace Manufacturing

There are several types of forming presses used in aerospace manufacturing, each serving specific purposes:

-

Hydraulic Presses: These are commonly used for forming complex shapes in aerospace components. Hydraulic presses offer high force output and precise control over the forming process, making them ideal for creating intricate parts with minimal material wastage.

-

Mechanical Presses: Known for their speed and efficiency, mechanical presses are used for high-volume production of simpler parts. They are suitable for operations where repeatability and consistent quality are critical.

-

Pneumatic Presses: These presses use compressed air to generate force. While they may not provide the same level of power as hydraulic or mechanical presses, they are useful for lighter materials and applications where high speed and precision are required.

-

Isostatic Presses: In aerospace manufacturing, isostatic presses are used for compacting powdered materials into dense, uniform shapes. This method is especially important for producing components that require exact material properties and microstructures.

Importance of Forming Presses in Aerospace

Aerospace components must endure extreme conditions, including high temperatures, intense pressures, and significant mechanical stress. Forming presses are critical in ensuring that these components are manufactured to meet stringent aerospace standards. The precision offered by forming presses allows manufacturers to produce parts with tight tolerances, reducing the risk of component failure.

Moreover, forming presses help in reducing material waste, which is a significant advantage in aerospace manufacturing, where materials like titanium and carbon composites are both expensive and challenging to work with. By enabling precise control over the shaping process, forming presses contribute to efficient material utilization, lowering production costs and environmental impact.

Advancements in Forming Press Technology

The aerospace industry continuously evolves, and so do the technologies that support it. Recent advancements in forming press technology include the integration of computer numerical control (CNC) systems, which enhance precision and repeatability. Additionally, the development of servo-hydraulic systems offers better control over force and speed, allowing for more complex and precise operations.

Furthermore, with the increasing use of advanced materials such as composites and high-strength alloys, forming presses are being adapted to handle these materials more effectively. Innovations such as hot forming and superplastic forming are now employed to work with these challenging materials, ensuring that aerospace components meet the required performance criteria.

Conclusion

Forming presses are indispensable in aerospace manufacturing, providing the necessary precision and control to produce high-quality components that meet the industry's rigorous demands. As technology continues to advance, forming presses will remain at the forefront of aerospace manufacturing, enabling the production of safer, more efficient, and more reliable aircraft components. For aerospace manufacturers, investing in the latest forming press technology is crucial to maintaining a competitive edge in an industry where excellence is not just expected but required.