Door Lamination Press

Introduction

Door lamination is a popular method for enhancing the appearance and durability of doors. The process involves applying a laminate layer onto the surface of a door to provide a finished look and added protection. The use of a door lamination press is critical in this process, ensuring that the laminate adheres evenly and securely to the door surface. This article delves into the working mechanism, benefits, types, and considerations of using a door lamination press.

What is a Door Lamination Press?

A door lamination press is a specialized machine used to apply laminate sheets to the surface of doors. It utilizes heat and pressure to bond the laminate to the door’s substrate, which can be made of materials like MDF (Medium Density Fiberboard), plywood, or solid wood. The press ensures that the laminate is uniformly adhered, avoiding bubbles, wrinkles, or loose edges.

Types of Door Lamination Presses

There are several types of door lamination presses, each designed to cater to different production needs and door types:

-

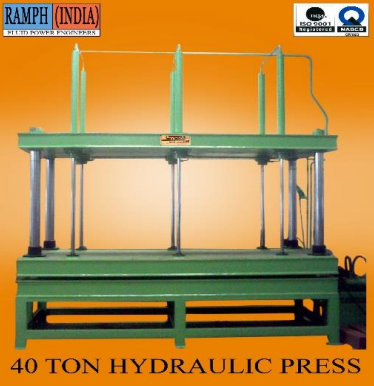

Hydraulic Lamination Press:

- Functionality: Uses hydraulic pressure to apply the laminate. This type is known for its ability to provide consistent pressure across the door surface, ensuring a strong bond.

- Applications: Suitable for high-volume production and large doors.

-

Vacuum Lamination Press:

- Functionality: Utilizes a vacuum to remove air between the laminate and the door surface before pressing them together. This ensures a bubble-free finish.

- Applications: Ideal for doors with intricate designs or when working with thin laminates that require a delicate touch.

-

Cold Press Lamination Machine:

- Functionality: Operates without heat, using only pressure to bond the laminate to the door. It’s often used for materials that are sensitive to heat.

- Applications: Best for small-scale production or for materials that may warp or deform under high temperatures.

-

Hot Press Lamination Machine:

- Functionality: Combines heat and pressure to bond the laminate to the door. The heat activates the adhesive on the laminate, creating a strong and durable bond.

- Applications: Commonly used in large-scale production where speed and efficiency are paramount.

Working Mechanism

The process of door lamination using a press involves several steps:

-

Preparation:

- The door surface is cleaned to remove any dust or debris, ensuring a smooth surface for the laminate to adhere to.

- The laminate sheet is cut to the appropriate size, slightly larger than the door to allow for trimming after application.

-

Application of Adhesive:

- An adhesive is applied to either the door surface or the back of the laminate. The type of adhesive used depends on the materials involved and the type of press being used.

-

Positioning:

- The laminate sheet is carefully positioned on the door surface, ensuring alignment with the edges.

-

Pressing:

- The door and laminate are placed in the press. Depending on the type of press, heat, pressure, or vacuum is applied to bond the laminate to the door.

- The duration of pressing varies based on the type of laminate, adhesive, and press used.

-

Trimming and Finishing:

- Once the pressing is complete, the door is removed from the press. The excess laminate is trimmed, and the edges are smoothed to create a finished look.

Benefits of Using a Door Lamination Press

-

Enhanced Durability:

- Lamination protects the door surface from scratches, moisture, and wear and tear, extending the door’s lifespan.

-

Aesthetic Appeal:

- Laminates come in a wide range of colors, textures, and designs, allowing for customization and enhancing the visual appeal of doors.

-

Cost-Effective:

- Lamination is a more affordable alternative to solid wood or other expensive materials, providing a high-end look at a lower cost.

-

Ease of Maintenance:

- Laminated doors are easy to clean and maintain, as the surface resists stains and dirt.

-

Uniformity:

- The press ensures that the laminate is evenly applied, resulting in a consistent finish without any imperfections.

Considerations When Using a Door Lamination Press

-

Material Compatibility:

- Ensure that the laminate and door materials are compatible with the press being used. Some laminates may require specific adhesives or pressing conditions.

-

Adhesive Quality:

- The quality of the adhesive plays a crucial role in the longevity of the lamination. Choose adhesives that are suitable for the specific materials and conditions.

-

Press Settings:

- Different laminates and substrates may require different press settings (temperature, pressure, and time). It’s important to follow manufacturer recommendations to avoid damaging the materials.

-

Maintenance of the Press:

- Regular maintenance of the press is essential to ensure consistent performance. This includes checking for wear and tear, lubricating moving parts, and ensuring the heating elements are functioning properly.

-

Operator Skill:

- Skilled operators are crucial for achieving the best results. Proper training ensures that the laminate is applied correctly and that the press settings are optimized for each job.

Conclusion

A door lamination press is an essential tool in the production of laminated doors, offering a combination of durability, aesthetic appeal, and cost-effectiveness. Whether used in large-scale manufacturing or small workshops, the press ensures that laminates are applied efficiently and consistently. By understanding the different types of presses, their working mechanisms, and the key considerations involved, manufacturers can optimize their lamination process and produce high-quality, long-lasting doors.