Areca Leaf Pressing Machine: Revolutionizing Eco-Friendly Packaging

In recent years, the push towards sustainable and eco-friendly products has gained immense traction, and one standout innovation in this movement is the Areca Leaf Pressing Machine. This machine is at the forefront of transforming areca leaves, commonly known as betel leaves, into biodegradable and durable packaging solutions. Here’s why the Areca Leaf Pressing Machine is making waves in the green technology sector and how it contributes to a more sustainable future.

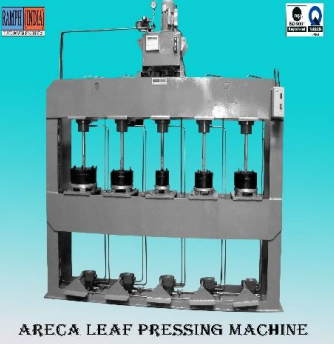

What is an Areca Leaf Pressing Machine?

An Areca Leaf Pressing Machine is a specialized equipment designed to convert natural areca leaves into a variety of eco-friendly products. These machines compress and shape the leaves into various forms, such as plates, bowls, and trays, without the need for synthetic additives or chemicals. The process leverages the natural strength and flexibility of areca leaves, resulting in a product that is both durable and compostable.

How Does it Work?

The operation of an Areca Leaf Pressing Machine is relatively straightforward. Fresh areca leaves are collected and cleaned before being subjected to a pressing process. The machine uses high pressure to compress the leaves into molds, shaping them into the desired forms. The pressing process involves heating the leaves to enhance their rigidity and durability, making them suitable for various applications. Once pressed, the products are allowed to cool and dry, ready for use.

Benefits of Areca Leaf Pressing Machines

-

Eco-Friendly: Areca leaf products are biodegradable and compostable, making them an excellent alternative to plastic and other non-degradable materials. The use of areca leaves helps reduce the environmental impact associated with traditional packaging and disposable items.

-

Sustainable Raw Material: Areca leaves are a byproduct of the areca nut industry. Utilizing these leaves for packaging helps in reducing waste and making productive use of what would otherwise be discarded. This approach aligns with the principles of circular economy and sustainable development.

-

Durability: Areca leaf products are not only eco-friendly but also durable. They can withstand heat and moisture, making them suitable for a range of uses from food packaging to disposable cutlery. Their natural strength ensures that they maintain their integrity even under challenging conditions.

-

Cost-Effective: The production of areca leaf products can be more cost-effective compared to synthetic alternatives, especially when considering the long-term environmental savings. The machine’s efficiency in processing and molding leaves translates into lower production costs and reduced waste.

-

Versatility: Areca Leaf Pressing Machines can produce a wide array of products, including plates, bowls, trays, and even customized shapes. This versatility makes them suitable for diverse applications across various industries, including food service, catering, and event planning.

Applications and Market Potential

The demand for eco-friendly packaging solutions is on the rise, driven by increasing consumer awareness and regulatory pressures. Areca leaf products are gaining popularity in restaurants, hotels, and events as a sustainable alternative to plastic and paper products. Additionally, their appeal extends to environmentally conscious consumers who prefer products that align with their values.

Conclusion

The Areca Leaf Pressing Machine represents a significant advancement in the quest for sustainable and environmentally friendly packaging solutions. By harnessing the natural properties of areca leaves, this machine not only provides a viable alternative to plastic but also supports the broader goals of waste reduction and sustainable resource management. As the world continues to seek greener solutions, the Areca Leaf Pressing Machine stands out as a testament to innovation and environmental responsibility. Investing in such technology not only contributes to a cleaner planet but also aligns with the growing market demand for eco-friendly products.